Co-extrusion

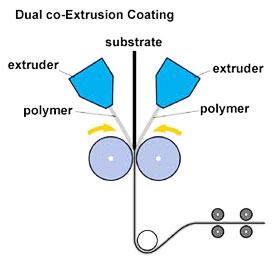

Co-extrusion is defined as the process in which two or more plastic materials are extruded through a single die. In this process, two or more orifices are arranged in such a manner that the conjoint merging and welding of the extrudates takes place and before chilling, a laminar structure forms. In co-extrusion, a separate extruder is used to fed every material to the die but the orifices can be arranged in such a manner that each extruder provides two or more plies of the same material. Co-extrusion is defined as the process in which two or more plastic materials are extruded through a single die. In this process, two or more orifices are arranged in such a manner that the conjoint merging and welding of the extrudates takes place and before chilling, a laminar structure forms. In co-extrusion, a separate extruder is used to fed every material to the die but the orifices can be arranged in such a manner that each extruder provides two or more plies of the same material.

Co-extrusion may be employed in the processes of Film Blowing, Extrusion Coating, and Free Film Extrusion. The general benefit of the co-extrusion process is that every laminate ply imparts a required characteristic property like heat-sealability, stiffness, & impermeability, all of which are impossible to attain by using any single material.

It is evident that co-extrusion is a better process than a single layer extrusion. For instance, in the vinyl fencing industry, co-extrusion process is used for tailoring the layers on the basis of whether these are exposed to weather or not. Generally, compound's thin layer is extruded that contains high-priced weather resistant additives. This extrusion is done on the outside, whereas inside there is an additive package which is more suitable for the structural performance and impact resistance.

Advantages Of Co-extrusion

According to various internationally established and popular companies that are using the co-extrusion process continuously in their production procedures, there are a number of advantages of this process. Some of these advantages are listed below:

- High quality mono-layer extrusion coatings in larger varieties of line speeds and widths

- Use of lower cost materials for filling purpose, assists in saving on the amount of qualitative resins

- Capability of making multi-layer as well as multi-functional structures that too in a single pass

- Reduction in the number of steps required in general extrusion process

- Provides targeted performance with the use of definite polymers in particular layers

- Reduction in setup and trim scrap

- Potential for use of a recycle layer

Disadvantages Of Co-extrusion

As per a number of globally reckoned companies, there are some disadvantages related with the process of co-extrusion. Some of these disadvantages are as follows:

-

Minor differences in physical properties are responsible for making a combination desirable, but these differences are also responsible for making the combination incompatible

- For this process, polymers must have similar melt viscosities to sustain a laminar flow. All the viscosity differences may be more or less tolerable, according to the material location inside the composite structure along with the layer's thinness

- Requires more sophisticated extruder and its operator. This implies extra maintenance cost of the equipment.

- Demands considerable planning as well as forethought in the system design

|

|