|

Forming Internal cavities and Drives

Introduction

In the plastic extrusion process there are several methods to form internal cavities. To create the hollow inside a device called mandrel is used, which is mistaken a bending die by some customers. Plastic materials like thermoplastics are prevalently used to create products with hollow insides like pipes and tunes for industrial and household applications. In the plastic extrusion process there are several methods to form internal cavities. To create the hollow inside a device called mandrel is used, which is mistaken a bending die by some customers. Plastic materials like thermoplastics are prevalently used to create products with hollow insides like pipes and tunes for industrial and household applications.

Process

Internal cavity forming extrusion process is same as other regular plastic extrusion process until the molten resin reaches the die. A mandrel is placed inside the die with the support of a long rod. The mandrel lies tangent to the bend. In most cases pressure is applied to the internal cavities through the mandrel. The molten resin flow divides and flows about the mandrel before the hollow profile is extracted out of the die. The mandrel is then extracted after the bending process is complete or within the last few degrees of bending. The plastic tube which is still molten is treated in a water bath in order to prevent the hollow pipe or tube from collapsing.

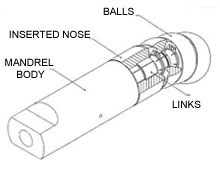

Mandrels

Mandrel is part of the plastic extrusion tooling set, but it is not used in most of the bending operations. It is the  device that is incorporated within the die to produce different round, square and rectangular cavities for tubings. Different types of floating, fixed and semi-floating mandrels are used for creating internal cavities. If multiple holes are to be produced, the tooling is made by placing more than one pin in the center of the die, so as to produce a number of holes. The type of mandrel required varies depending on the wall thickness of the tube, radius required, and type of material being bent. device that is incorporated within the die to produce different round, square and rectangular cavities for tubings. Different types of floating, fixed and semi-floating mandrels are used for creating internal cavities. If multiple holes are to be produced, the tooling is made by placing more than one pin in the center of the die, so as to produce a number of holes. The type of mandrel required varies depending on the wall thickness of the tube, radius required, and type of material being bent.

The mandrels or pins have a a long leg to hold it in place. The mandrel actually goes inside the tube and is held by a mandrel rod to support the tube at the tangent point of the bend. Special press is also used to control the mandrel independently from the ram. Mostly, the internal mandrel of a tubing or pipe die is maintained in centered position by means of a large number of arm-like support generally referred to as spider.

Features of the product

Continuous research is being made to introduce mandrels and dies that will help in improving the physical characteristic or uniform physical properties. The most difficult parts is the maintenance of the physical strength of the resultant product. Minor change in the width of the die gap will effect the uniformity of the thickness of the gauge. Therefore, care must be taken to check the gap width and also to allow unrestricted flow of the resin through the die. |

|

|

|